HSE QUESTIONS AND ANSWERS

SAFETY STANDARDSHELMET: --------------- Z-89.1 1981 (ANSI) *5240 (BS)

SAFETY GLASS:--------- Z-87.1 1968 (ANSI) *2092 (BS)

SAFETY HARNESS------ Z-359.1 & Z-10.14 (ANSI) *1397 (BS)

SAFETY SHOES---------- Z-41.1 1967 (ANSI)

RESPIRATOR------------- Z-88.2 1992 (ANSI)

SAFETY ON SCAFFOLDING—A-10.4 1988 (ANSI)

1. What is Work Method Statement (W.M.S.)?

Ans: It is the document submitted by contractor to client, covering the general work procedure of a particular job in a safe manner as per required standard.

2. What is the use of W.M.S.?

Ans: We can plan and execute the work easily and safely. It also helps to know the Codes and Standards used for each activity.

3. What is JSA and what is it use?

Ans: Job Safety Analysis is the step by step analysis of a job to determine the safe working procedure. It includes the following steps.

A. Watch the job being done

B. Breaking the job down into steps

C. Describe the hazards in each step of task

D. Identify the desired control measures

E. Implement these counter measures in the job execution

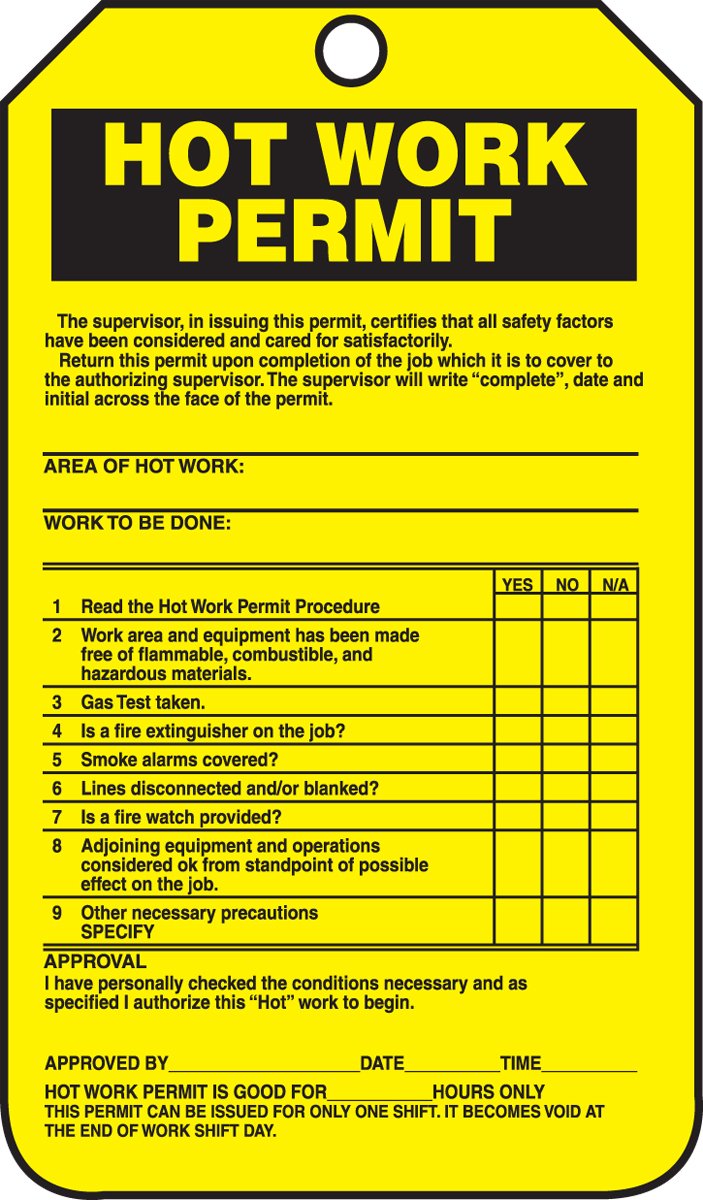

4. What is Work Permit?

Ans: Work Permit is the written document authorizing a person or a group to perform maintenance, inspection, or construction work.

5. What is a Confined Space?

Ans: Any space having a limited means of access or egress, which subject to the hazards like deficiency of oxygen, toxic or flammable gases or substances, dust etc.

6. In what circumstances a confined space work permit can be issued?

Ans: If properly ventilated, gas test readings are satisfactory, properly barricaded and warning signs are posted, trained standby man is present with log sheet, sufficient lighting and low voltage electricity (24V-110V), proper means of communication, locked and tagged out if necessary, lifeline and man retrieval system if necessary, etc.

7. Who is a Confined Space Attendant?

Ans: He is one who is aware of the confined space hazards and know how to react if anything goes wrong, able to maintain confined space entry log sheet etc.

8. What are the hazards in a confined space?

Ans: Oxygen deficiency or enrichment, present of toxic or flammable gases, chemical hazard, fire hazard, fall of materials, fall hazards, electrocution, dust, sound, heat or cold, caught in between moving parts of equipments, engulfment, etc.

9. What are the duties of a confined space attendant?

Ans: He is responsible for the safety of entrants, should be present whenever people are working in confined space, maintain update entry log sheet, maintain continuous communication with entrants and monitor conditions in the confined space to ensure a safe working atmosphere, prevent unauthorized entry of personnel, initiate alarm for help if needed, evacuate the entrants if conditions are not satisfying or incase of any general evacuation is initiated, contact rescue personnel if necessary, etc.

10. Give some examples of a Confined Space?

Ans: Pipes, Vessels, Tanks, Boilers and Tubes areas, Silos, Trenches and Excavations deeper than 4feet, Sludge pits, Duct works, etc.

11. Name one hazardous job in a Confined Space?

Ans: Welding, grinding, chemical cleaning, use of gas cutting set, erection of materials.

12. Who is a competent person?

Ans: Is one who is properly trained and authorized to perform a specific work in a safe manner.

13. What is an accident?

Ans: An accident is an uncontrolled event that results in undesirable consequences to personnel (injury/illness) or the assets (damage/loss) to the environment.

14. What is near miss?

Ans: A potential hazard, which not yet caused an accident or an occurrence that did not result in but have the potential to result in undesirable consequences to personnel (illness/injury) and/or to the assets (damage/loss) or to the neighboring community and environment.

15. Who make an accident report?

Ans: Concerned area supervisor or site safety representative.

16. Who makes an accident investigation report?

Ans: A team of front line supervisor, HSE manager, Sub-Contractor representative if sub-contractor personnel are injured, high officials depending upon the severity of accident.

17. What is the use of the accident investigation report?

Ans: To find out root cause of the accident, make recommendations to prevent re-occurrence and evaluate the effectiveness of emergency response.

18. What is waste management?

Ans: Waste management means safety disposing the by-product of a process or a work to the environment (after proper treatment, if necessary) so that no threat for livings, properties and environment exists.

19. What is MSDS?

Ans: Material Safety Data Sheet is the document prepared by the manufacturer giving product name, producer’s address, emergency contact phone number, information of ingredients, possible hazards, first aid measures, precautions to be taken for storage and handling (recommended PPE, extinguishers), physical and chemical properties, etc.

20. What is Isotope?

Ans: Isotope means one or more species of atoms having same atomic number but different mass number.

Isotope can be stable or unstable. Radioactive isotopes are unstable substances, which emits heavy particles (alpha and beta) and higher energy electromagnetic waves (Gama) from their nucleus by decay.

21. Why is an Isotope hazardous?

Ans: Isotopes are hazardous because it emits uncontrolled energy in the form of radioactive waves which is hazardous to all living things as it can destroy the its living tissues that causes fatality or can convert it in cancer.

22. What is radio activity?

Ans: Radio activity is the spontaneous disintegration of atomic nuclei, the nucleus emits ALPHA particles, BETA particles, GAMA particles, or electromagnetic rays during this process.

23. What is the unit for measuring radiation?

Ans: Micro Silver or Milli - Rem.

24. In what condition a work permit can be issued for Radiography?

Ans: The controlled area is calculated, evacuated and barricaded with yellow/black tapes, warning signs (a minimum of 4 nos.), and red or yellow flash lights.

25. What are the safety measures to be taken while doing radiography?

Ans: Ensure a competent person is surveying outside the barricaded area with survey meter. The crew is authorized and following safety precautions. The controlled area is calculated, evacuated and barricaded with yellow/black tapes, warning signs (a minimum of 4nos.), and red or yellow flash lights.

26. What is the controlled area?

Ans: Any area where the radiation dose is more than 0.75 mRem/h (7.5 micro sivert).

27. What is a Gieger meter?

Ans: It is the instrument used to measure the radiation dose (Radiation Survey Meter).

28. What is the used of a film badge?

Ans: This badge will be worn by personnel, exposed to radiation due to their nature of duty and this is processed to calculate the received radiation dose of a person during the period (normally 1 month) of exposure.

29. What is a decay chart?

Ans: It is the chart showing the change in radioactivity of a source, for a period, at regular interval of time.

30. Who is an authorized exposed person?

Ans: He is one who got formal training in the used of sealed source and x-ray equipment used in industrial radiography.

31. What are the requirements of a man basket?

Ans: It should be designed and fabricated according to standards, have third party certificate, two guide ropes, damage free lifting gears, the load bearing capacity should be written on the man basket, shackles with cotter pin only to be used.

32. How are slings inspected?

Ans: All slings must be inspected before every use and periodically it should be inspected thoroughly and should be rejected, if found wear of one third the original outside diameter of outside individual wires, severe corrosion, distortion (kinking, crushing, bird-caging), broken wires (a maximum of 10 randomly distributed broken wires in one rope lay or 5 broken wires in one strand in one rope lay), heat damage (loss of internal lubricant by over heat exposure), pulled eye splices (any evidence that eye splices have been slipped, sleeves damage) deformation of wires and strands or pushed out of their original position and the sling should be clean from dirt or rust. Before use of the slings has to be color coded as per the month color code.

33. What are the requirements for a crane lifting?

Ans: Crane positioned on firm and level ground with wood pads and steel plates. Outriggers are fully extended, tires are off ground, certified operator and rigger are available, safe load indicator is working, the check list is filled with competent person, crane has a valid inspection sticker, insurance and third party certificate, the loads weight is confirmed and it is within the safe working limit of the crane, safety devices are not bypassed, the swing arm radius is barricaded and unauthorized people are evacuated, the lifting tools are free from defects, pads are used to protect the slings from load and vice-versa, wind speed is less than 32 kmh, approved lifting plan is available for critical lifts, permit for the activity is obtained, crane operators and riggers vision is not obstructed, the load is well balanced, and tag lines are used to control the weight etc.

34. What is working radius?

Ans: It is the maximum distance where the crane boom has to reach for lifting or lowering the load.

35. What is SWL?

Ans: Safe Working Load is the maximum load that can be applied to the lifting tool, safely.

36. What is lifting plan?

Ans: It is the document prepared for planning a critical lift by calculating and considering all factors which is going to effect the lift and there by selecting the correct tools and cranes and ensure the safe lifting procedure to be followed for the particular lift, giving details such as the size and weight of the object to be lifted, which crane is used for lifting and what the safety factor is, where the crane is positioned, from where the load is lifted, where it is fitted, size and SWL of each lifting tool used. And load chart is attached with it.

37. What is a excavation?

Ans: A man made cut, cavity, trench or depression formed by earth removal.

38. What is a trench?

Ans: A narrow excavation, where the depth is grater than the width.

39. What is shoring?

Ans: A structure that support the sides of an excavation and protect against cave-ins.

40. What is the difference between a flash-back arrestor and a check valve?

Ans: A check valve allows flow in one direction only. This prevents oxygen reaching acetylene cylinder and acetylene reaching oxygen cylinder in the event of blockage in the torch or line or pressure variations.

But a flash back arrestor prevents reverse flow, stops the flow of flame from reaching the cylinder in the event of a flash back or the temperature exceeds a limit (220 deg F).

41. What are the classes of fire and what type of extinguishers are used for them?

Ans: Class A: Ordinary combustible materials

Ex: Paper, wood, cloth, plastic, rubber

Extinguisher- Water, DCP, Foam, CO2, Halon

Class B: Combustible liquids and gases

Ex: Gasoline, diesel, oil, grease, oil based paint, tar

Extinguisher- CO2, Foam, DCP

Class C: Energized electrical equipment

Extinguisher- DCP, FM-200, Halon, Carbon Dioxide

Class D: Combustible metals

Ex. Magnesium, Potassium, Zinc, Calcium, Sodium, Titanium

Extinguisher- Metal X-type, Combustible metal type.

Ans: Fire watch is a person designated to identify and eliminate fire hazards, alert and extinguish fire incase of any outbreak of fire and to protect the person and properties from a fire. He is the man to react first incase of fire by keeping a close watch on such hazardous areas.

43. What is color coding system?

Ans: This is the system followed to inspect and ensure the serviceability of tools, equipments periodically (normally it is monthly) like fire extinguishers, full body harness, lifting gears, electrical codes and cables, power tools, etc. These things are inspected by combatant person and are indicated by putting the color of particular month (this color is decided in advance and is being followed by all people at particular site). The items which are found defective or unserviceable will not be color coded and has to be removed from service.

44. Who can color code?

Ans: Competent Person.

45. What is the maximum distance between two adjacent accesses in a long excavation?

Ans: A ladder must be present within 25ft., of employees working in excavation.

In open excavation – At every 30 meters on the perimeter, if less than 1.2 meters deep.

- At every 7.5 meters on the perimeter, if more than 1.2m deep.

46. What is an excavation considered as a confined space?

Ans: If depth is more than 1.2 meters.

47. Who can erect a scaffolding.

Ans: Certified scaffolder.

48. Who can inspect the components used for erecting a scaffold?

Ans: A competent and certified scaffolding supervisor.

49. What is a tag system?

Ans: A tag is put on scaffolding, by a competent person, indicating the present condition whether it can be used and whether fall protection needed or not.

Red Tag: Do not use (Is being erected of dismantle)

Yellow Tag: Can be use with 100% fall protection (is incomplete or cannot be completed)

Green Tag: Safe to use (Scaffolding is complete)

50. Who can place a scaffold tag?

Ans: Competent person (Scaffolding Supervisor).

51. What are the details in a scaffolding tag?

Ans: Location, Maximum loading capacity (kN/m2 or psf); Date erected and date inspected with foreman’s name and signature.

52. In which conditions a scaffold cannot be erected?

Ans: Extreme weather (strong wind, rain, ice), ground not stable, safe clearance (minimum 10ft.) cant be maintained with live wire, certified workers and supervisor are not available, permit not available.

53. What is the minimum overlapping of two adjacent planks in a scaffold platform?

Ans: Not less than 12 inches

54. What is a guard rail system?

Ans: A barrier consisting of top rails, midrails, toe boards and vertical uprights erected to prevent men and materials falling from an elevated work area.

55. What is a toe board?

Ans: Barrier secured along the sides and ends of a platform to guard against falling of materials, tools, and other objects.

56. What is the minimum height of a toe-board?

Ans. 4 inches.

57. what is the height of top rail from platform?

Ans. 38 to 45 inches.

58. In what circumstances fall protection system to be used?

Ans. If a person could fall more than 1.8 meters then a fall protection system should be used.

E.g. Any activity at an elevation more than 1.8 meters such a erection, dismantling or maintenance of scaffolding, pipes, equipment,…

59. what is the minimum width required for a walk-way?

Ans. Minimum width of walk way is 18”.61.

60. what materials can be b placed on a scaffold platform?

Ans. All types of construction materials when is used for particular construction activity can be kept on scaffolding platform but before keeping the materials and tools required fro the work on the platform, we must ensure load bearing capacity of that scaffolding platform. The platform shall not be over loaded and shall be fitted with falling object protection system like toe board, nets etc.

61. What are the minimum requirements for working on a scaffold?

Ans. Mobile scaffolding shall be plumb, level and square. It shall only be used and moved on a surfaces sufficiently firm and level to ensure stability. It shall be move only by manually pushing or pulling the base. No men equipment or materials shall be on the working platform or elsewhere on the scaffolding while it is in motion. Castor shall be locked at all times except during scaffold movement. The temporary foundation or track set on uneven ground for scaffold movement shall be level and properly secured. The height of the working platform shall not exceed 4 times of the minimum base dimension. If it exceed this limit outriggers must be installed. A complete guard rails system must be provided. The scaffolding shall be inspected and tagged before use by a competent person.

62. when should we inspect a scaffold?

Ans. A scaffold shall be inspected and tagged after completing erection. Also before each work period or where they are altered. Adjusted or subjected to rain or heavy winds.

Thereafter the scaffold shall be examined at least once seven days.

63. With what color a ladder can be painted?

Ans. Aluminum ladders and wooden ladder shall not be painted.

64. What is life line?

Ans. A life line is a component that consist of a flexible line that connects to an anchorage at one end to hang vertically or that connect to anchorages at both ends to stretch horizontally and which serves as method to connect other component of a personnel fall arrest system to the anchorage.

65. How can we calculate the safe anchorage of a life-line?

Ans. When life line is used they shall be fastened to fixed safe points of anchorage capable of supporting 2300 Kgs. Shall be independent, and shall be protected from sharp edges and abrasion. Safe anchorage points may include structure members (minimum 4” structural member or 4” pipes) but do not include guard rails, vents, other small dia piping systems, electrical conduit, outrigger beams or counter weights. It shall be made from 10 mm dia. Width ropes. Horizontal life lines shall be installed at the highest feasible point, preferably above shoulder height. This life lines shall be maintained with unloaded sag at the centre no greater than 30 cm (12 inches) for e very 10 meters of life line length between attachment points

66. What is Lock out/ Tag out system?

Ans. For servicing or maintenance of live equipment or pipe lines, where the unexpected energizing or release of energy could cause injury, lock and tag are placed on the isolating device to avoid uncontrolled operation and give details of the lock-out schedule.

67. Expand the following:

•STARRT- Safety Task and Risk Reduction Talk

•COSHH- Control of substance hazardous to Health.

•OSHA- Occupational Safety and Health Administration.

•OSHAS- Occupational Health and Safety Assessment Series.

•ELCB- Earth Leakage Circuit Breaker.

•GFCI- Ground Fault circuit Interrupter.

•BS- British Standard \institute.

•SWL- Safe working Load .

•ANSI- American National standards Institute.

•LTI- Lost Time Incident.

•ASTM- American Society for Testing of Materials.

•JSA- Job Hazards Analysis.

•LEL- Lower Explosive Limit.

•UEL- Upper Explosive Limits.

•PEL- Permissible Explosive Limit.

•REL- Recommended Exposure Limit

•PSI- Pounds/Square Inch ( 1 bar= 14.7 psi)

•STEL- Short Term Exposure Limit.

•WBGT- Wet Bulb Globe Temperature

•APR- Air Purifying Respirator

•ASR- Air Supplying Respirator.

•SCBA- Self Contain Breathing Apparatus.

•RSO-Radiation Safety Officer

•NFPA- National Fire Protection association

68. What is the importance of a Tool box meeting?

Ans. The workers can be educated about safe rules and procedures, and their awareness can be improved on some special task its importance.

69. What is an Emergency Evacuation Plan?

Ans. It is the procedure to provide concise guide lines for evacuation in case of some emergency and to identify the emergencies in advance. This also helps us to plan and to define roles and responsibilities of all building custodian fire wardens and occupants.

70. What is a Hydro Test?

Ans. It is the test carried for leak test for pipes, equipments etc by filling water in these equipments and pipes with some pressure and its joints and connection are checked for any leak or breakage.

71. What is a Hipot- Test?

Ans. It is the insulation leakage test done for high voltage electrical cables, with high voltage megger.

72. What are the safety requirements for doing a hot work?

Ans. a). Remove all combustible materials from the area(with 10 mm), possible.

b). Use fire blanket to protect immovable materials and also for welding slugs.

c). Cover the area with fire blanket for containment of park generated while doing hot work.

d). Provide proper fire extinguisher in sufficient numbers.

e). Appoint a fire watch with red jacket, If necessary.

f). Barricade the area and post proper signage.

g). Use of proper PPE and damage free tools and equipment.

h).Obtain a valid hot work permit.

i). Conduct gas test if presence of combustible gases expected prior to work.

72. What are the benefits of near miss reporting?

Ans. To make analysis of the incident in order to avoid re occurrence.

To rectify the cause of those near misses before it turns into accidents.

To identify the deficiency of site performances and final remedial actions.

To improve safety performances by reducing LTAs, incident and near misses.

73. What is a risk assessment?

Ans. risk assessment is a method of estimating the rate of risk of an activity, by classifying actual and potential consequences and finding out mitigating actions to limit that risk.

74. In what situation Ear protection is needed?

Ans. In areas, where sound pollution is more than 85 dBA.

75. what is the emergency evacuation procedure to follow in the event of gas release ?

Ans. don’t get panic on hearing alarm.

Switch off all the equipment and energized circuits.

Observe the direction of wind flow, proceed out in the cross wind direction to the plant boundary fence and then proceed up wind.

Obey further instructions from emergency response team.

Resume work after getting clearance only.

76. what is an “Assembly Muster Point”?

Ans. The area determined and marked for assembly of people working in case of any emergency.

OTHER INTERVIEW QUESTION FOR HSE

1. What is the difference between Risk and Hazards?

2. Explain Flash Back Arrestor?

3. Name any ten types of Hazards?

4. List the main causes of accidents with suitable examples.

5. What is the difference LMI and Anti Two Block?

6. What is MSDS?

7. What is PASS in the use of fire extinguisher?

8. List the requirements for a Crane to work at site?

9. List the main parts of a scaffold?

10. What is the difference between JSA and STA?

11. What are the points to be considered for an excavation safety inspection?

12. List the safety requirement for working at height?

13. List the safety Hazards in confined space?

14. List the Safety points for storage and use of Compressed Gas Cylinders?

15. What is CABA?

16. List the documents to be checked during Administrative Audit?

17. What do you understand by 100% tie off?

18. List the document to be audited during HSE Audit?

19. Explain HSE Policy statement?

20. List the requirements to be met for approving an Hot Work Permit?

21. What is IDLH?